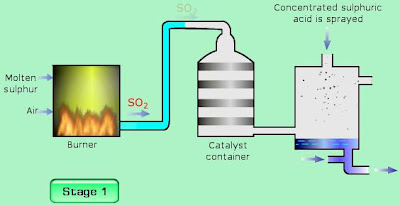

The manufacture of sulphuric acid is called Contact Process.

The raw materials required in contact process are sulphur, air and water.

The contact process involves THREE stages of chemical reactions as below:

Stage I : Production sulphur dioxide, SO2

Sulfur is burnt in dry air in the furnace to produce sulphur dioxide.

S + O2 → SO2

Stage II : Conversion of SO2 to SO3

Pure SO2 reacts with oxygen in catalytic converter to produce sulphur trioxide at a temperature between 450°C to 550°C.

2SO2 + O2 → 2SO3

This stage requires catalyst vanadium(V) oxide.

Stage III : Production of sulphuric acid

In the absorber, sulphur trioxide is dissolved in concentrated sulphuric acid to produce oleum, H2S2O7.

H2SO4 + SO3 → H2S2O7

Oleum is the diluted in water to produce two molecule of sulphuric acid.

H2S2O7 + H2O → 2H2SO4

SO3 gas is not directly dissolved in water to produce H2SO4 because the reaction releases large amount of heat and is able to vaporize sulphuric acid and produces acid mist.

Among the uses of sulphuric acids are:

i. to manufacture fertilizers

ii. to manufacture detergent

iii. to manufacture paint pigment

iv. to remove metal oxide from metal surface

v. to manufacture pesticide

vi. as the electrolyte in lead-acid accumulators

The burning of products manufactured from sulphuric acid will produce SO2. The SO2 dissolved in atmospheric water vapour to produce acid and subsequently causes the acid rain.

SO2 + H2O → H2SO3